Challenge

Engineer a scalable, fleet-wise, edge-to-cloud data infrastructure for live insights and long-term, operational and position data.

IQIP is a dominant and innovative OEM of pile driving and pile handling equipment. A project was initiated to (1) provide end users with live insights on project progress and system state, and (2) give IQIP’s internal engineers long-term, operational and position data. Therefore, we engineered and implemented a scalable, fleet-wise, edge-to-cloud data infrastructure.

Engineer a scalable, fleet-wise, edge-to-cloud data infrastructure for live insights and long-term, operational and position data.

The Helin Platform: a scalable edge-to-cloud infrastructure.

Our platform provides IQIP with insightful KPI's, a scalable infrastructure, remote access, high resolution sensor data and API access.

There were several key challenges when engineering the ideal data infrastructure for IQIP’s pile driving and pile handling equipment.

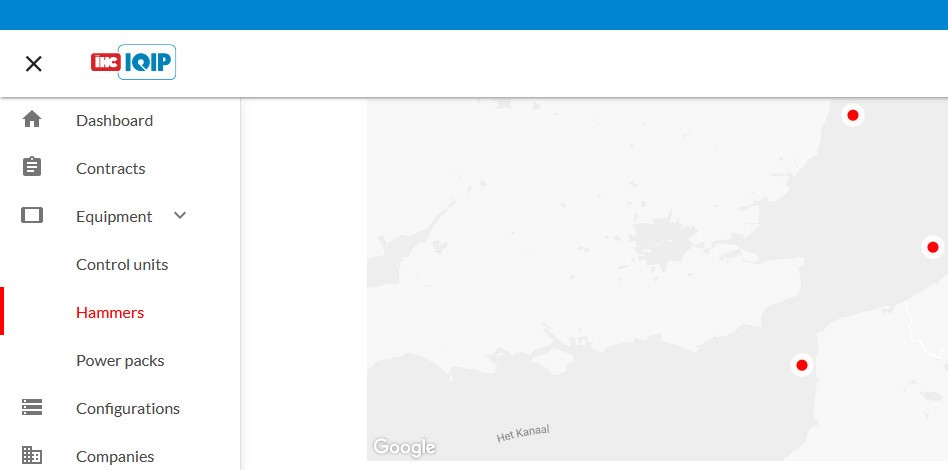

IQIP’s mobile equipment operates world wide at remote locations. This could be offshore in the North Sea or on a tundra in Russia. To be able to monitor live, edge data has to be transferred via e.g. 4G/LTE or SatCom to the cloud environment. These connectivity challenges have to be dealt with.

The equipment includes pumps and other rotating equipment. Data acquisition at the edge needs to be at sampling frequencies of at least 50Hz. In addition, there are multiple industrial protocols like ModBus, CANbus, OPC UA and MQTT that need to be combined.

The equipment is either owned by the operator or rented to them by IQIP. For the renters, in particular, this means that the users change frequently. Obviously, operational data may not be shared between them. Any data infrastructure needs to take care of data security and segmentation.

The pile driving and pile handling equipment consist of multiple components. Depending on the project at hand these can be combined into multiple configurations. Data acquisition and especially data analytics has to take these different configurations into account.

We designed and implemented a scalable edge-to-cloud infrastructure based on our edge-to-cloud platform. This infrastructure consists of the following components.

A robust IP 67 cabinet was engineered with an internal Helin Platform node. This cabinet was mounted onto one of the structures of the remote equipment. It automatically powers on when the whole system is powered. Measures are taken to cope with frequent transport, power losses, variable connectivity and more. The node pre-processes high-resolution data, buffers it in case of connectivity loss and allows for remote access to update and manage configuration of the systems settings.

All the configured data is streamed into the IQIP cloud node in Microsoft Azure. Extensive authentication and authorization measures are taken to ensure that only the right data is accessible to the right person. New edge nodes can be added and managed from the cloud node. This provides great control to IQIP’s admin user and allows for future scaling of the overall infrastructure.

A RESTful API enables the integration with the user portal and makes data available for in-depth analysis. This provides a robust foundation for any future use cases and integration with third-party systems. Most importantly, it allows for an intensive root cause analysis in case of unexpected systems failures, for examples.

The edge-to-cloud data infrastructure provides IQIP and its customers with a strong foundation for several major use cases, namely user engagement, root cause analysis and predictive maintenance.

The KPIs are used for project management and monitoring, improving performance and reducing project cost.

The platform edge-to-cloud infrastructure scales from a limited deployment up to including the full fleet.

The technical and service department is able to access the piling equipment remotely and update and manage configurations.

The platform edge nodes ingest sensor data at high resolution, up to 100Hz for edge analytics and in-depth condition monitoring.

The RESTful API utilizes the power of the platform solution by allowing easy integration with other systems and user portals.

Want to learn more about this case? Or what we can do for you? Contact us today.